How can digital transformation and automation in Smart Factories drive energy reduction and speed up the transition to a sustainable future?

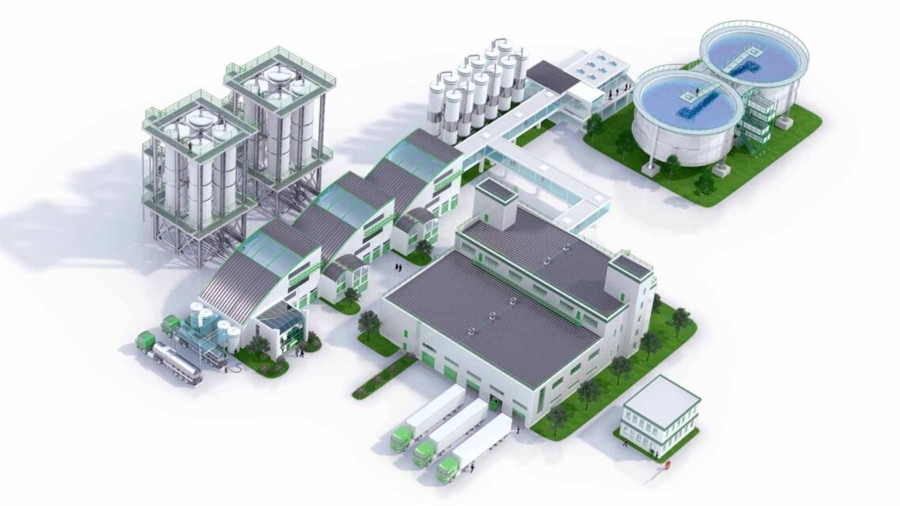

Schneider Electric helps make Smart Factory operations innovative and sustainable through an end-to-end digital transformation that improves operational efficiency and reduces energy consumption and CO2 emission. As an industrial technology leader with IoT and data analytics expertise, Schneider Electric's digital energy strategy for smart factories leverages IIoT connectivity, Edge analytics, and predictive analytics to drive energy efficiency and sustainability goals.

Discover EcoStruxure, our IIoT-enabled system that offers smart solutions for manufacturing that help reduce energy and maintenance costs across our Smart Factories and Smart Distribution Centres. Our Smart Factories, recognised by the World Economic Forum, lead the way in manufacturing with the latest digital tools, including augmented reality, remote monitoring, and predictive maintenance, to save energy, carbon footprint, and overall cost savings, while offering increasing agility and resiliency within the operation. Our scalable smart solutions with end-to-end cybersecurity for supporting applications and data analytics enable operators to view cloud-connected critical data anytime, anywhere, and from any device.

Benefits of smart manufacturing

Smart manufacturing, powered by advanced technologies like IoT, AI, and automation, offers numerous advantages. It enhances efficiency by optimizing production processes, reducing waste, and improving resource utilisation. Real-time data analytics enables proactive maintenance, preventing equipment failures and downtime.

Moreover, smart manufacturing enhances product quality through precise control and monitoring. By integrating data across the supply chain, businesses can improve decision-making and respond swiftly to market changes. Ultimately, smart manufacturing drives innovation and competitiveness in today's rapidly evolving industrial landscape.