Motor management solutions

Watch how our holistic motor management solutions can optimize motor availability and increase savings.

Motor management

We help you to optimize and simplify your motor management solution while maintaining the performance of your operations and processes.

Discover five areas of motor management

Get to know motor management applications

Each application segment contains various offers in motor direct starters, protection, soft starters, and variable speed drives based on key priorities.

Explore our offer for machine applications

Discover our motor management solution architectures for machines to lower cost optimization and boost machine’s performance.

Explore our offer for process applications

Increase safety and energy efficiency and decrease downtime with our targeted processes and infrastructure installations.

Check our resources

Explore our offer for building applications

Utilize our solutions dedicated to buildings and ensure improved safety of people and assets.

Check our resources

Check our digital tools for seamless interactions

1. What is motor management?

Electrical motor management is usually associated with the overall maintenance of the motor; however, it is not limited to that. Our motor management holistic approach helps end users, equipment manufacturers, and designers coping with mechanical, electrical, and maintenance challenges for motors, controls, equipment selection and sizing, power factor, harmonic mitigation, and service continuity.

Our offer supports sustainable motor integration in electrical systems for industrial, machine and building applications. Made up of 5 pillars, it involves expert services and software for motor applications, advanced motor control, power quality, motor protection and control systems and asset management. An efficient motor management can help with reducing impact of motors during start-up and operation, increase power quality and production efficiency, reduce costs of unscheduled downtime or upkeeping, eliminate unnecessary inventory build-up, and more.

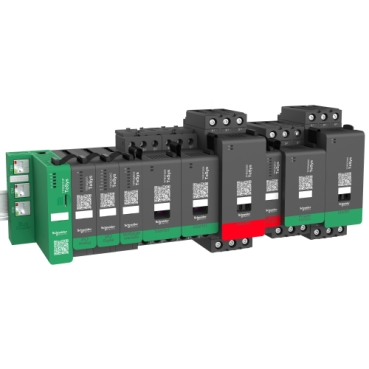

2. Motor management solutions by Schneider Electric

Our motor management solutions are based on properly designed and selected advanced technologies, robust power system architectures, motor control configurators, and motor management design tools for machines, processes, and buildings.

Our architectures can be divided into two broad categories:

- Digitized architecture, performance-driven and fully connected with transparent data reporting. It is instrumental in efficient energy management and power quality management.

- Core architecture, offering balanced performance, contactor, soft starter, and variable speed drive solutions.

3. Why a motor management program?

Our motor management program enables installation maintenance and management by supporting cost-effective decisions whenever a motor fails. It will help you reducing downtime and energy costs, ensuring that replacement motors are readily available.

This electric motor management program includes multiple motor and equipment aspects as power feeding, motor control and protection, motor control panel integration, system integration, and asset management. In addition, we offer simple, reliable, and tailored motor management systems that will help you meeting the requirements of demanding applications such as material handling and packaging, onsite maintenance, and others. We also provide a selectable thermal trip class, and our products maintain accurate operation under extreme temperatures, ensuring that the desired level of protection is achieved.