1. What are Schneider Electric solutions for industrial robotic automation?

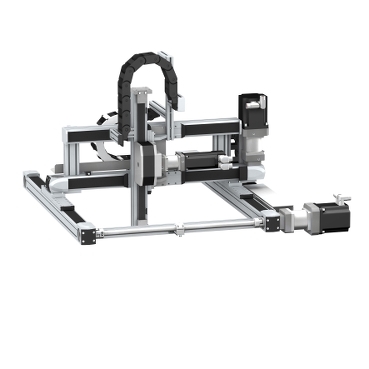

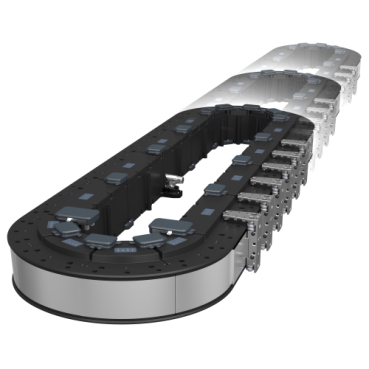

As a robust digital transformer and smart robotics and transport systems partner, we help machine builders, original equipment manufacturers (OEMs), integrators, and end users easily implement end-to-end integrated robotics solutions, answering the needs for mass customization while reducing costs and time to market. Our Lexium line of smart industrial robots and transport systems enables real-time synchronization, high-speed motion, as well as precise positioning and handling.

2. What are the benefits of implementing our industrial robotic automation solutions?

Implementing our industrial robotic solutions — digitally designed from concept to operation and maintenance and integrated into one machine control architecture — can help you benefit from a high payoff at every stage of the lifecycle. From reducing design and time-to-market by up to 50% to time savings in commissioning time by up to 60% and on corrective actions by up to 50%. EcoStruxure, our open, IoT-enabled architecture with a digital twin at the core, helps you simplify the integration of industrial robotics into the machine control solution to answer the challenges of smarter manufacturing, more flexible and sustainable while improving employee safety and welfare. Partnering with us also relies on our robotics experts and partners’ networks available worldwide.

3. How can we help you better understand the benefits of industrial robotic automation solutions?

Embracing industrial robotics automation solutions as a tool for sustainability is also a step toward a more sustainable future for the planet overall and for businesses in such sectors as machinery, food and beverage, life sciences, logistics and warehousing, battery manufacturing, and semiconductor. It enables us to provide a safer work environment, while ensuring sustainable outcomes, such as reducing energy consumption and waste, tracking, and lowering emissions for internal operations and smoother production. Learn more on our training platform.