Oxford Energy Solutions: Customer Story Key Figures

50-70% less energy needed

Improved equipment reliability and lifecycle

Drastically reduced operating and maintenance costs for end users

The Challenge

Innovative refrigeration specialist Oxford Energy Solutions wanted to help its customers:

- Modernize 50-year-old systems to make them more efficient and sustainable

- Eliminate the need for lubrication in refrigeration components

- Improve visibility into operating thresholds

- Increase flexibility, reliability, and functionality

- Reduce maintenance and repair costs

The Solution

Apps, Analytics & Services: EcoStruxure Machine Advisor, EcoStruxure Secure Connect Advisor

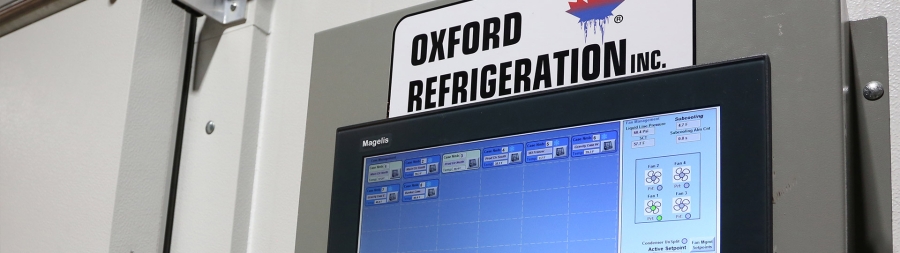

Edge Control: Modicon M172 logic controller, EcoStruxure Machine SCADA Expert

Connected Products: Altivar Machine 320 variable speed drives, Harmony iPC and pushbuttons, Telemecanique sensors, TeSys U motor starters, PowerLogicTM EM3500 power meters, power supplies, switches, contactors, motors, transducers

Oxford Energy chose to implement a full suite of EcoStruxure Machine solutions, including:

- The Modicon M172 logic controller, which allows for a better-operating, lower-charged system with fewer connection points and gaskets

- EcoStruxure Machine Advisor with EcoStruxure Machine SCADA Expert and a Harmony iPC, which provide visibility into every step of the refrigeration process and provide alerts should any issues arise

- EcoStruxure Secure Connect Advisor, which adds a security layer and helps protect the system

The Results

- 50%-70% less energy requirements (from 21 Kw/h to 6 Kw/h) for refrigeration systems

- 50% reduction in the number of mechanical components in the systems’ design

- Improved equipment reliability and lifecycle

- Drastically reduced operating and maintenance costs for end users

- Remote monitoring and predictive maintenance capabilities

- All devices integrated into a single connected automation system that can be easily expanded as necessary

Learn more about our offer

Smart machines with EcoStruxure Machine

EcoStruxure Plant & Machine

Digital services for industrial automation

Smart HVAC control solutions