Sanning Chemical: Customer Story Key Figures

25-30% improvement in workforce efficiency

5% reduction in energy consumption

Safe and stable operations

The Challenge

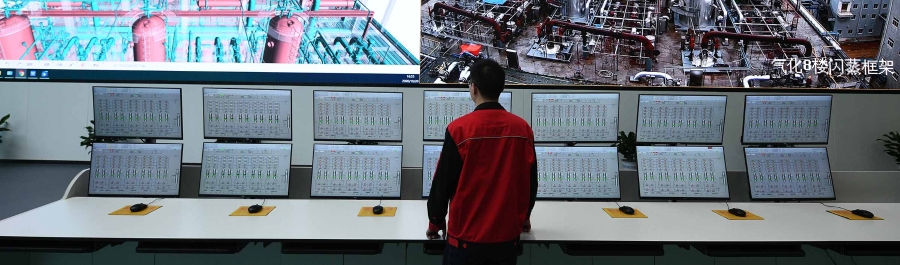

For a comprehensive upgrade to its huge ethylene glycol facility, Sanning Chemical was looking for a digital solution to achieve:

• Safe and reliable production in a hazardous environment

• Reduced operating costs through greater efficiencies

• Compliance with stringent environmental requirements, including energy consumption

• Digital transformation

• Protection of its massive capital investment in upgrade project

• A tight delivery schedule

The Solution

Apps, Analytics & Services: AVEVA Asset Information Management*, AVEVA Operator Training Simulator (OTS)*, AVEVA InTouch HMI*, AVEVA PI System*

Edge Control: EcoStruxure Triconex Safety Instrumented System, PMBox Easy

Connected Products: Altivar drives (ATV930 and 1200), PIX MV cabinets, MasterPact MTZ air circuit breakers, LV inverters

*The Schneider Electric industrial software business and AVEVA have merged to trade as AVEVA Group plc, a UK listed company. The Schneider Electric and Life is On trademarks are owned by Schneider Electric and are being licensed to AVEVA by Schneider Electric.

Edge Control: EcoStruxure Triconex Safety Instrumented System, PMBox Easy

Connected Products: Altivar drives (ATV930 and 1200), PIX MV cabinets, MasterPact MTZ air circuit breakers, LV inverters

*The Schneider Electric industrial software business and AVEVA have merged to trade as AVEVA Group plc, a UK listed company. The Schneider Electric and Life is On trademarks are owned by Schneider Electric and are being licensed to AVEVA by Schneider Electric.

The Results

• 25-30% improvement in workforce efficiency

• 5% reduction in energy consumption

• Faster time-to-operation with remote operator training using digital simulation

• Safe and stable operations

• Improved operational and maintenance efficiencies and power supply continuity

• Future-proof solution through end-to-end digitization

• 5% reduction in energy consumption

• Faster time-to-operation with remote operator training using digital simulation

• Safe and stable operations

• Improved operational and maintenance efficiencies and power supply continuity

• Future-proof solution through end-to-end digitization

Learn more

EcoStruxure for Energies and Chemicals

EcoStruxure Triconex Safety Instrumented Systems