EcoStruxure Plant Apps industrial IoT software solutions running on CONNECT services with AVEVA Data Hub deliver the best of Schneider Electric application knowledge suited for major industries.

The EcoStruxure open, scalable, cybersecure, AI-based IIoT solutions optimize multi-site operations efficiency, reduce operating costs, accelerate solutions deployment and return on investment (ROI), and simplify governance by leveraging a single data platform.

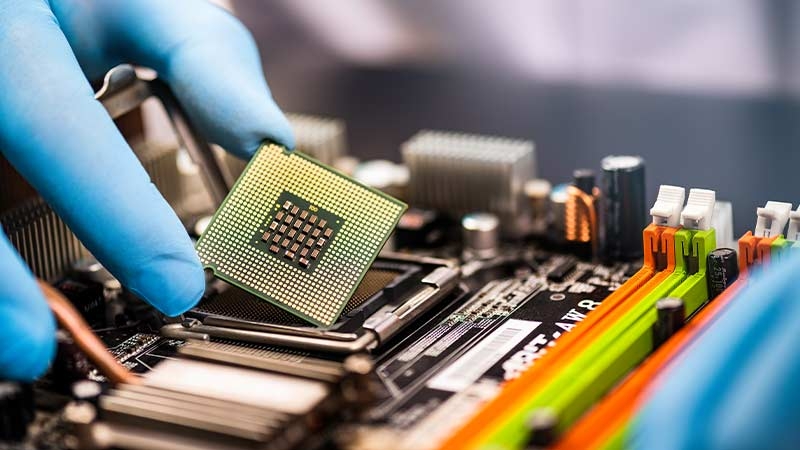

They are designed to meet the needs of the Automotive, Food and Beverage, Life Sciences, Mining and Cement, Semiconductors, Transportation, Warehousing, and Water industries as a few examples.