The good news is that demand for reductions in these critical areas is giving rise to innovation. Developments in circularity and product lifecycle design, biofuels, and other technologies are helping companies get closer to net zero.

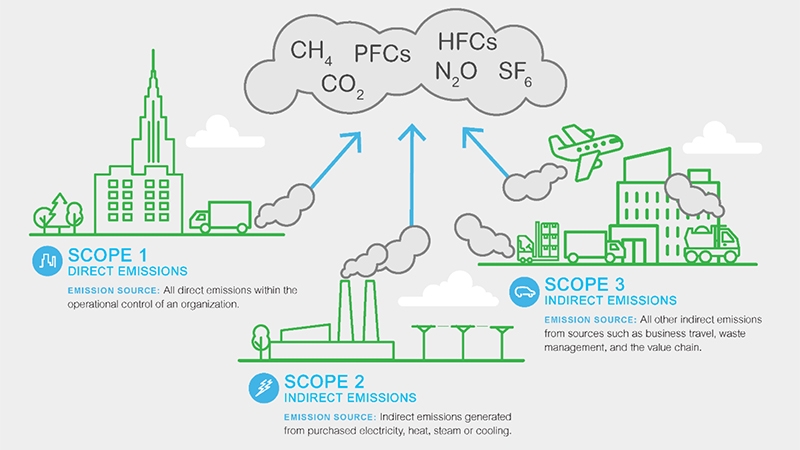

Not all GHGs are created equalRethinking how to do business becomes even more critical in these areas when it comes to the types of emissions being produced. While electricity generation primarily results in CO2 emissions, a host of other greenhouse gases (GHGs) live in the broader operational footprint. These include methane (CH4), nitrous oxide (N2O), and hydrofluorocarbons (HFCs), perfluorocarbons (PFCs), sulphur hexafluoride (SF6), and nitrogen trifluoride (NF3), known collectively as F-gases.

These GHGs are not created equal when it comes to their global warming potential (GWP), which is a measure of the potency of each GHG. For reference, CO2 has a GWP of one (1). The GWPs of other GHGs is a measure of how much heat they trap in the atmosphere up to a specific time horizon, relative to CO2. For example, CH4, one of the other most prominent atmospheric GHGs, has a GWP of around 30. This means that emissions of 1 million tonnes of CH4 cause the same heating effect of approximately 30 million tonnes of CO2. [To equitably compare all GHGs, relative size of contribution and GWP for other gases is converted into measure of carbon dioxide equivalent (CO2e) when included in an emissions footprint].

Today, anthropogenic non-CO2 GHGs represent 25% of global emissions. The most recent Intergovernmental Panel on Climate Change (IPCC) report points out the importance of concurrent deep reductions in non-CO2 GHG emissions, especially methane, along with net zero CO2e emissions to limit global warming to 1.5 °C.

The role of SF6 in the electrical industrySF6, while relatively rare in the atmosphere, has a GWP of 23,500, and is the most potent GHG. It is an odorless, non-toxic, and highly stable gas used in a variety of industrial and scientific applications, including as a propellant, an etchant, and an insulant. The majority of SF6 is used in the electrical industry as a dielectric medium that provides a high performance, safe, and economically convenient solution for electrical insulation and current interruption.

Providing sustainable alternatives to SF6 and other high potency GHGs in industrial use and production is one important approach to overall GHG management. F-gas reductions often require their use to be addressed at each phase of the product lifecycle. During manufacturing, leakage can occur when filling products. During use, leakages are possible as a result of incorrect maintenance or product failure. It is at end of life when leaks and atmospheric dispersal are most likely. When managed properly, SF6 can be recycled or destroyed, which reduces the need for future SF6 production or neutralizes its GWP.

An occasion to innovateWorldwide, regulations are increasingly targeting SF6 due to its potency, and more restrictions can be expected in future years. For instance, SF6 has already been banned in the EU under the F-Gas Regulation, except in the electricity industry where there were few suitable alternatives available. And in California, proposed legislation is weighing the possibility of prohibiting the sale of SF6-based equipment after 2025.

Electrical equipment manufacturers are innovating to find new, SF6-free solutions to address environmental challenges of the 21st century. These innovations enable the passing of such restrictions and hasten the adoption of greener technologies. For example, today, there are SF6-free alternatives for medium voltage switchgear, representing a significant step in the right direction in the fight against global heating. As more regions adopt F-gas regulations, similar opportunities for innovation will surely arise.

Developing a comprehensive GHG reduction strategyIt is critical for companies to reduce their emissions across all GHGs; the higher the concentration of GHGs in the atmosphere, the greater the planetary heating and the greater the potential that we will experience the worst predicted impacts of climate change.

But how should companies prioritize their GHG reduction strategies? Which emission source should they seek to treat first?

The answer is a comprehensive one. Companies should create a strategy that accomplishes reductions across all three emission scopes and explores mitigation paths for non-CO2 GHG emissions. How each company approaches this strategy differs. Some may set an aggressive, all-encompassing goal from the beginning. Others may start with easy-to-achieve solutions. The most important step is to begin.

We recommend the following:- Start by measuring your organization’s GHG footprint to understand your emissions baseline.

- Next, set a publicly announced goal for reductions and consider having the goal verified by a 3rd We encourage you to be aggressive, as recent research conducted by Schneider Electric indicates that ambitious, publicly announced goals help companies move faster and more confidently.

- Then, develop and implement a plan that includes:

- Emissions avoidance when possible

- Emissions reductions achieved by:

- Improving the efficiency of energy consumption throughout the organization by implementing enterprise-level efficiency programs

- Addressing electricity emissions through renewable energy procurement

- Reevaluating fuel and gas use and adopting alternatives where available

- Considering the implementation of circular business practices that reevaluate product design and further reduce or eliminate specific greenhouse gases like SF6

- High quality, verified carbon offsets that neutralize the environmental impact of emissions that cannot be eliminated

- Engagement of suppliers, customers, and other stakeholders to achieve similar results

Schneider Electric’s global Energy & Sustainability Services team can work with your company at each step of the process to help you effectively set and reach your emissions goals. Please contact us today.

Schneider Electric is bringing SF6-free solutions to the market, starting with our new medium-voltage switchgear technology. Let our tech be part of your solution. Learn more here.