1. What is PAC and PLC?

Programmable automation controllers (PACs) and programmable logic controllers (PLCs) are open-architecture computing systems that help automate industrial processes. Companies use PLCs and PACs as equipment and machine control tools. There are, however, several differences between PACs and PLCs. These are reliability, ruggedness, ease of programming, memory and processing power, and the programming language used for control and management (ladder logic vs. ladder logic with C and C++).

2. What is the purpose of PAC and PLC?

The companies use these single-platform devices to monitor data from the sensors. Then, they use this information to control the operation of machines and equipment. It helps them make decisions based on the collected data and communicate with other devices that are part of the digitally operated system. These options are also great for logging and storing data. PACs and PLCs provide diagnostics, which is the key for future troubleshooting.

3. What are the benefits of our courses?

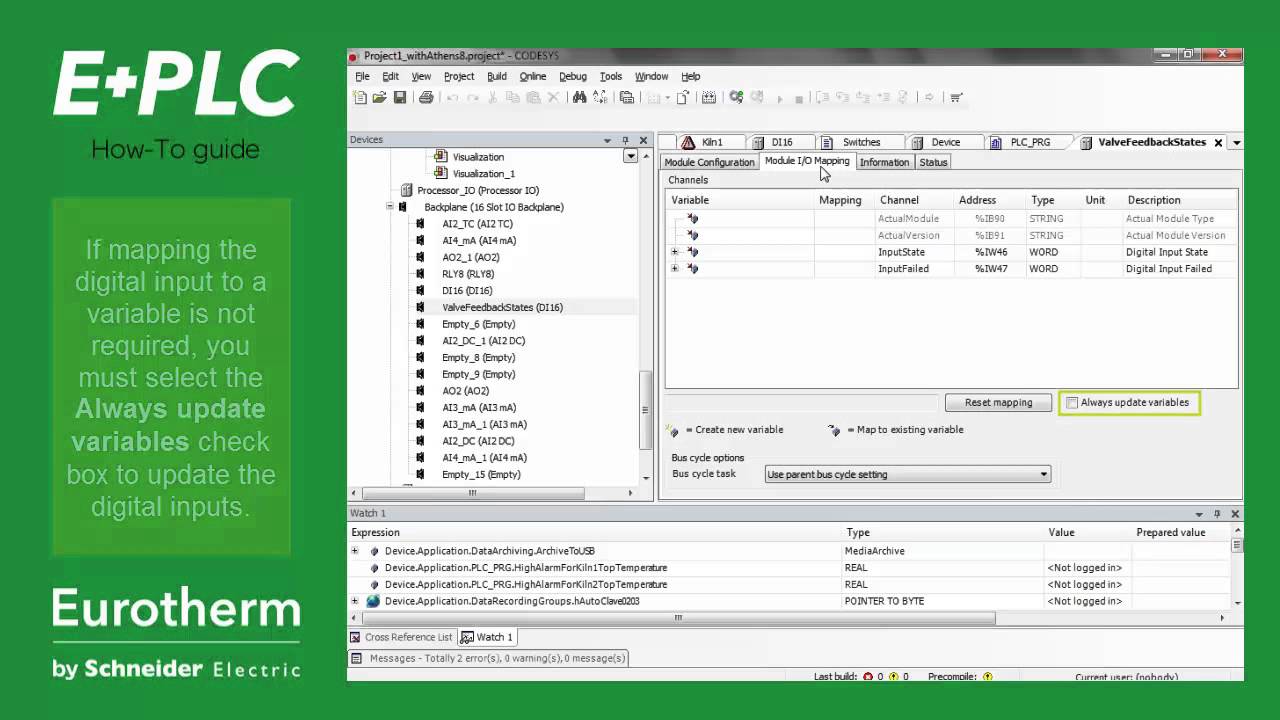

The guides presented on the page offer how-to videos on PLC training and PAC training with complete instructions. There, you can choose the tutorial that is best suited to your demands. It means picking up the guide with all the information regarding the model. In that way, you get to know the features and characteristics of PACs and PLCs.

Another benefit of the Modicon training is the expertise they give to all the customers. With a smooth and beginner-friendly approach, users learn the key elements that allow for better effectiveness. In turn, this translates into better industry performance and reduced costs while using these control systems.